Performance Management

at HAMMONIA Reederei

As a leading ship management company we provide performance management services in order to ensure all vessels in the HAMMONIA fleet are operated at maximum efficiency.

Current market conditions in the shipping industry, as well as environmental legislation are the main drivers to reduce the fuel consumption of our fleet.

Ship operators chartering HAMMONIA vessels will strongly benefit from the performance management services provided. Fuel costs can account for more than 40% of the total operating expenses of modern vessels. Hence, reducing these costs and ensuring maximum vessel availability and schedule conformity is a main priority at HAMMONIA.

However, reducing fuel consumption is not only a cost optimization issue. Shipping accounts for up to 15% of global man-made greenhouse gas emissions. HAMMONIA Reederei has recognized that the shipping industry has a social responsibility to reduce its environmental footprint. Working together with ship operators, HAMMONIA assists in the strive to facilitate more environmental friendly global trade.

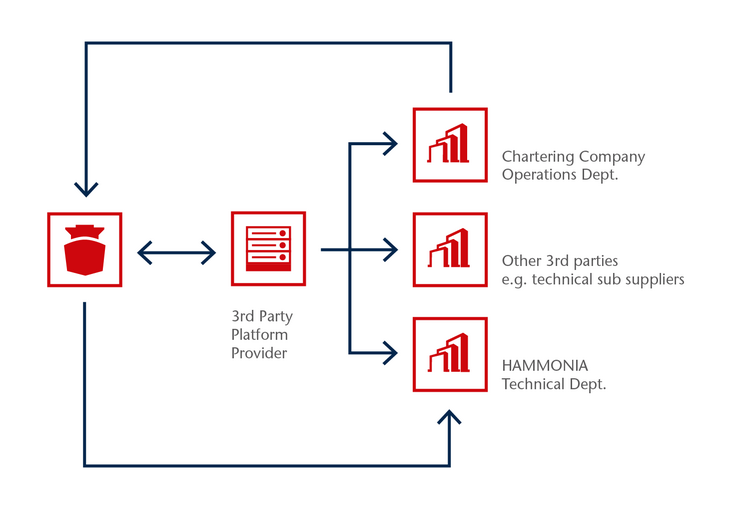

In order to achieve ambitious targets, HAMMONIA utilizes the value of big data. By collecting manually reported and automatically measured data, KPI’s are monitored against benchmark values. Since 2012 HAMMONIA has developed the required IT infrastructure as well as a web-based analysis platform.

Our platform approach enables us to monitor and efficiently manage the performance of all HAMMONIA vessels. The ship performance management is broken down into two main areas of focus: operational performance and asset optimization.

Measures to optimize shipping assets through retro-fitting and conversions:

A majority of ship types within the HAMMONIA fleet have undergone extensive research on how to reduce the energy consumption through modification of the hull structure, appendages and machinery. Depending on vessel particulars, some of the below listed options provide interesting business cases to reduce operational costs and increase vessel flexibility.

Hydrdynamic performance optimization

- Hullform optimization (bulbous bow renewal)

- Propulsion efficiency optimization

- Replacing propeller

- Reducing losses in wake field (through propeller boss cap fins and rudder bulbs)

- Improving propeller inflow through nozzles

Main engine derating

- Reducing specific fuel consumption at low loads

- Cutting out turbo chargers

- Reducing auxiliary loads

Cargo capacity increase

- Increase deadweight capacity

- Increase container stacking heights

Measures to drive

operational performance:

Hull and propeller condition based monitoring

- Ensure optimal hull and propeller cleaning intervals

- Monitor performance of anti-fouling

Voyage planning and weather routing

- Assistance through in-house nautical expertise

- Weather routing software provided to all vessels